Overview

KOA pump is a centrifugal pump of horizontal, single-stage, single-suction and cantilevered type, and is designed as per DIN24256, ISO2858, and GB5656.

This series of pumps have reliable, stable and efficient hydraulic performance. The performance points meet the requirements of international standards. Pump structure is simple and reliable; the versatility is strong; also the maintenance is convenient and simple.

Application Range

This series of pumps are mainly used in chemical, petrochemical, refinery, coal chemical, power plant, paper industry, pharmaceutical industry, sugar industry, food, steelmaking, waste acid treatment, water supply and drainage, urban water supply, food deep processing as well as other industries. .

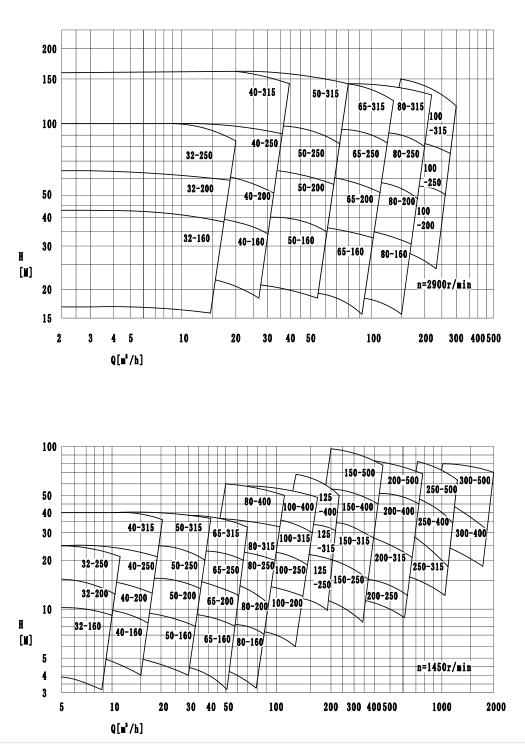

Performance Range

Flow range: 2~2000 m3/h

Head range: ~160m

Applicable temperature: -40~170°C

Design pressure: 2.5MPa

Structural Features

① The impeller has a back blade or balanced hole structure to balance the axial force, and the residual axial force is absorbed by the bearing.

② The bearing is lubricated with thin oil, and the constant oil cup and visual oil window are used to control the lubricating oil level.

③ A bushing is used to protect shaft to prevent it from medium contact. This structure avoids shaft to be corrosive by medium. It can improve the service life and reliability of the shaft.

④ It is not necessary to dismantle the pipes at inlet and outlet, and the motor by the rear drag design. The entire rotor component can be pulled out from the rear for easy maintenance.